LCD显示屏生产厂家

菜单

菜单

将质量和合规性放在首位

厂房面积2400㎡,拥有LCD液晶显示屏行业高级工程及管理人员20人,员工50余人。公司拥有国内一流的切割机、清洗线、POL贴片机、COG、FOG、点胶机、背光组装、焊接机等,主要COG粘接生产线3条,万级无尘车间月生产能力800K以上。

质量-泓彩保证

我们运营的基石是我们对质量和符合国际标准的坚定承诺。我们的LCD显示屏生产线不仅证明了我们的全自动生产和品质能力,也证明了我们对质量的执着追求。我们严格通过了各种质量管理体系的认证,包括 ISO 9001 和 2015 版管理体系等。该认证强调了我们在所有运营中保持最高质量管理和持续改进标准的承诺。

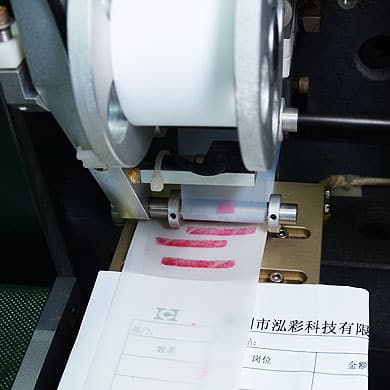

邦定设备

>校准精度um每周一次

0%

直通率

>产品一次性合格率

0%

性能检测

>3次电性能和稳定性试验

0%

生产车间

生产设备

5

+

检测设备

1

+

每天产能

8000

+

质量管理

值得信赖的合作伙伴

质量-在每个生产中可见的过程

我们努力成为TFT LCD液晶显示屏领域的最佳合作伙伴,为客户提供最新的创新和高品质的产品以及及时的服务。我们的质量控制和质量保证部门是我们流程的支柱,每一位员工和部门都支持他们,使他们组成了一条出色的产品和服务装配线。我们的高素质和经验丰富的QA和QC团队使用最先进的生产和检测设备,以确保在我们的产品制造中使用的每种原材料和组件都在受控环境中进行识别,选择和测试。

质量标准

我们的认证

温度检测

确保IC和LCD液晶显示屏面板的邦定温度

水平检测

确保IC和LCD液晶显示屏面板邦定平面平整

气压检测

测试IC/FPC和LCD液晶显示屏面板的邦定压力

COG/FOG检测

IC/FPC和LCD液晶显示屏面板ACF邦定粒子的检测

实验设备

RGB和亮度分析仪

冷热冲击设备

震动设备

FPC拉力检测

盐雾实验

CTP检测